The Grooved Cultivation Trough for Substrate Bag Growing Systems is a specialized hydroponic growing system designed to optimize nutrient delivery and root aeration for crops grown in substrate bags such as coco coir, expanded clay aggregates, and perlite. This system is ideal for commercial hydroponic greenhouse operations, urban farms, and indoor smart farming projects focusing on high-efficiency and high-yield cultivation.

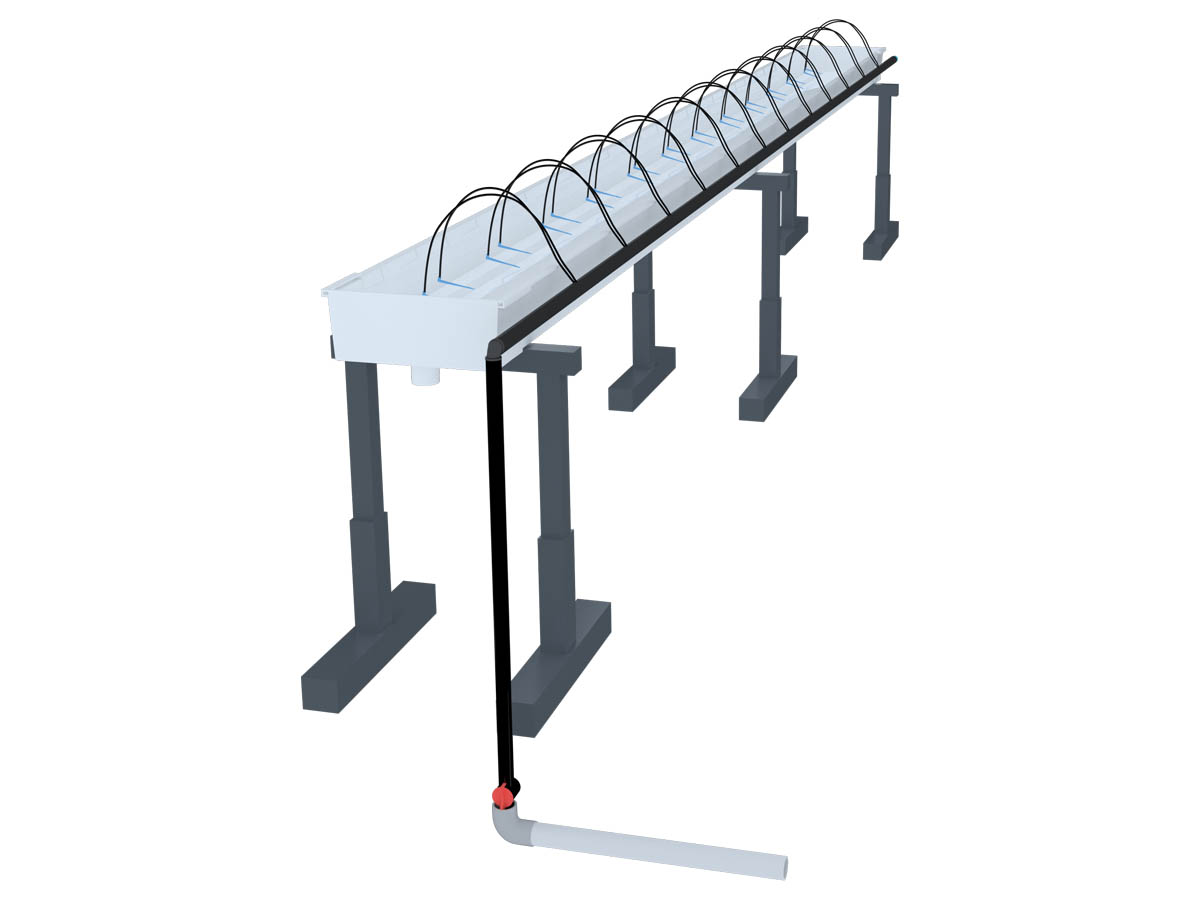

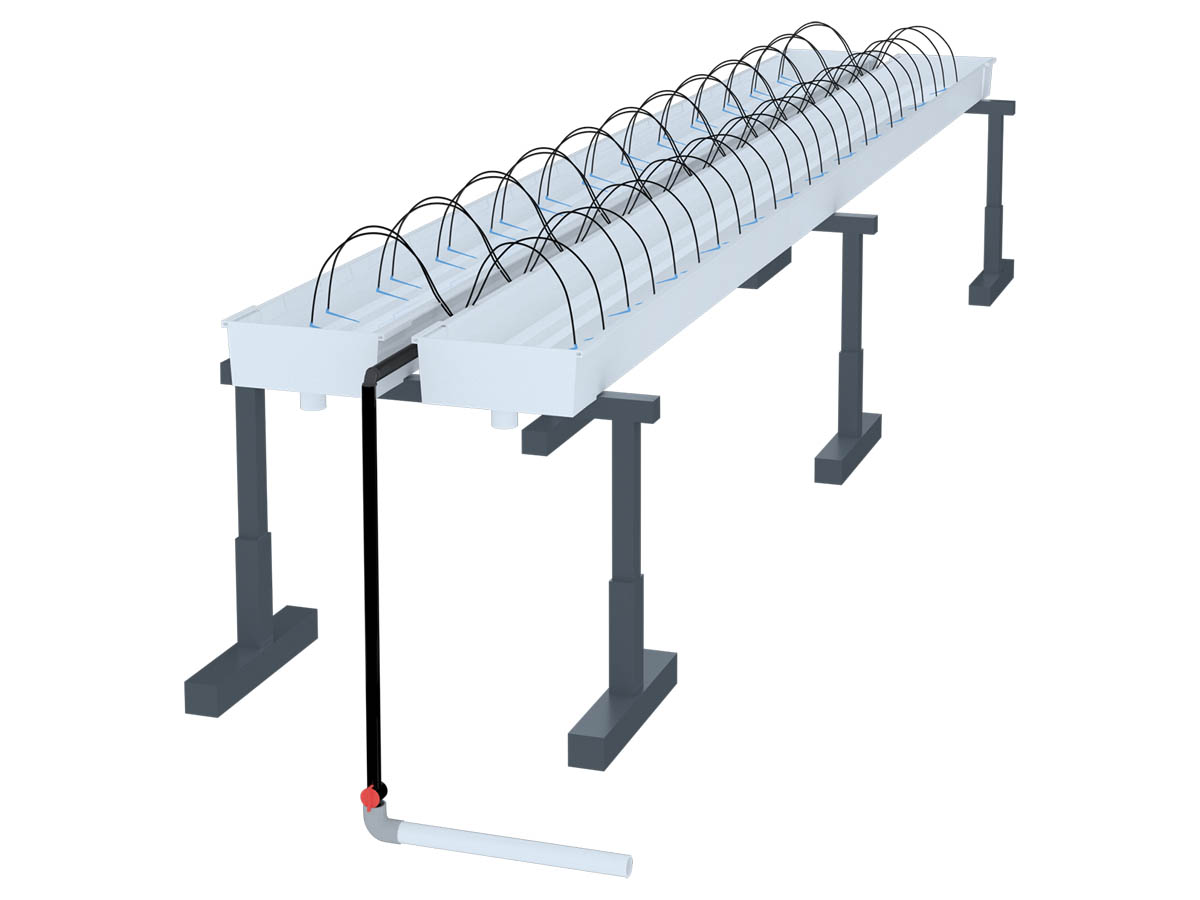

Single Row | Double Row | Triple Row |

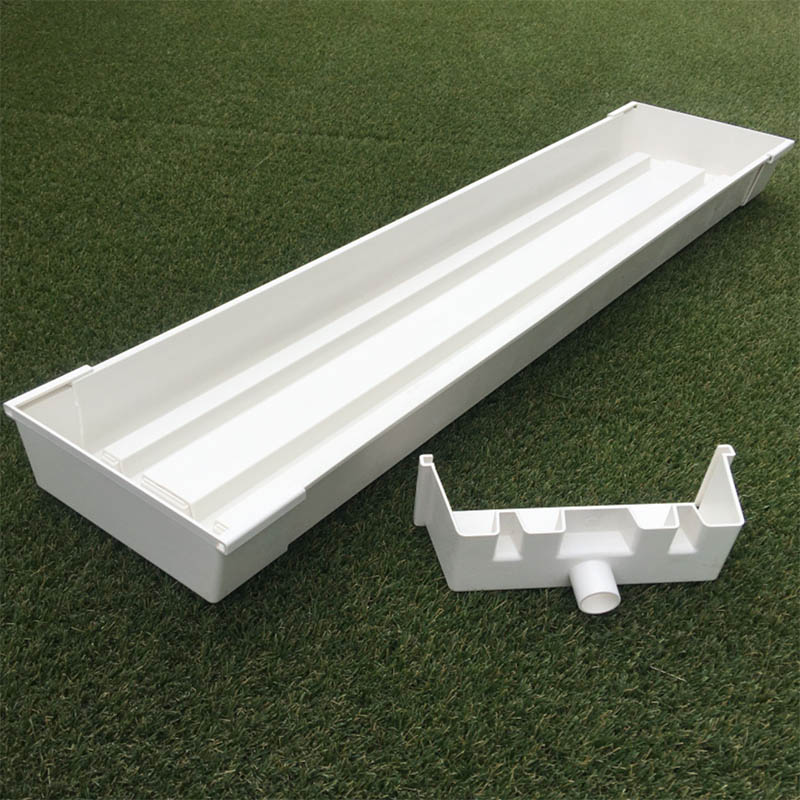

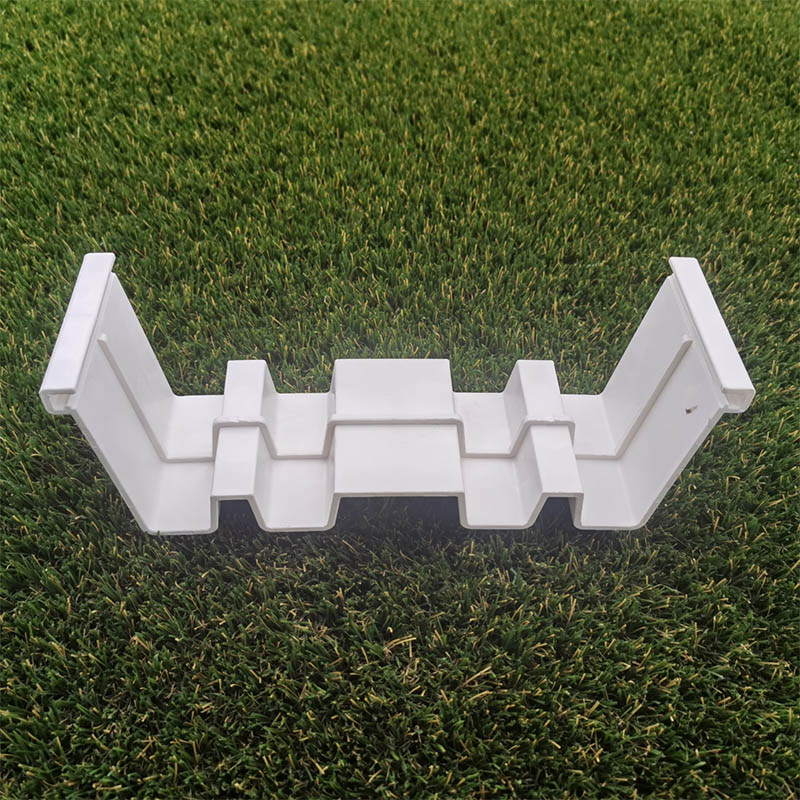

Substrate Trough (Grooved Type) |  End Cap with Outlet |  End Cap with Outlet Rod |  Pipe Cap |

|  |  |  |

|  |  |  |

Innovative Grooved Trough Design: The precision-engineered grooves within the trough ensure even distribution of nutrient-rich solution across the substrate bags. This prevents waterlogging and promotes optimal oxygen supply to roots, critical for healthy plant development in substrate gutter and gutter hydroponics applications.

Compatibility with Various Substrates: Designed to accommodate diverse growing media such as coco coir, perlite, and expanded clay aggregates, supporting robust root systems for crops like vine tomatoes, cucumbers, chili peppers, and leafy greens.

Modular and Scalable: The trough system is modular, allowing flexible configurations suitable for vertical hydroponic systems, urban farms, and indoor hydroponic gardens. It can be adapted to different greenhouse sizes and supports integration into comprehensive hydroponic growing systems.

Efficient Drainage and Overflow Management: Equipped with strategically placed drainage and overflow outlets, enabling seamless connection to centralized PVC pipelines. This facilitates water recirculation and waste reduction, essential for sustainable hydroponic farming practices.

Manufactured using durable, food-grade materials resistant to corrosion and biofilm formation, the grooved cultivation trough ensures long-lasting hygiene and operational stability. Each unit undergoes stringent quality inspections including flow rate calibration and leak-proof testing, guaranteeing compliance with international standards for hydroponic garden equipment.

Our commitment to quality ensures consistent crop performance and supports commercial growers in maximizing yield and profitability.

With advanced manufacturing processes and efficient supply chain management, G AND N FORTUNE LIMITED offers this grooved cultivation trough at competitive prices without compromising quality. Our production capacity and logistics network enable timely delivery worldwide, accommodating urgent orders and large-scale projects alike.

Installation & Operation Support: Detailed installation guides and instructional videos are provided to facilitate smooth system setup. Our technical team offers 24/7 online assistance and global on-site commissioning and training services.

After-Sales Service: Prompt troubleshooting and maintenance support help minimize downtime and optimize system performance.

Customizable Solutions: We collaborate closely with customers to tailor trough dimensions, materials, and automation features, ensuring the system perfectly fits crop types, growing media, and environmental conditions.

Commercial hydroponics farm cultivation of vine tomatoes, leafy greens, and other substrate-grown crops

Urban indoor hydroponic grow system projects requiring efficient substrate management

Scalable vertical hydroponic system installations for space optimization

Sustainable hydroponic greenhouse farming and smart agriculture

Precision grooved design for uniform nutrient distribution and superior root oxygenation

Durable, food-safe construction ensuring hygiene and long-term use

Cost-effective, scalable system adaptable to diverse farming scales

On-time global delivery supported by robust production and logistics

Comprehensive technical support and tailored customer service